Aircraft Designs

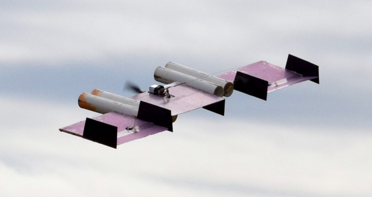

SAE Aerodesign Micro Class - 2019 - Buzz Squared

The challenge for this year’s competition was to fit an aircraft in a box with its full payload: 2.75” outer diameter PVC pipes. The box is only 3.75” thick, meaning that there is very limited place to fit the aircraft inside the box. This aircraft would fit inside a 13’’x12’’x3.75’’ box, and assemble to a flight ready condition in 25 seconds.

As the team lead, I completed sizing trade studies, coordinated between structures, propulsion and controls subteam to make sure all subsystems were interfaced. I also planned and executed flight tests oriented around on-design and off-design missions. I conducted trade studies to find the most optimal position for payloads to be placed inside the wing to minimize bending loads on the wing.

Awards Earned:

1st Place Design Report

2nd Place Overall

1st Place Payload Fraction

SAE Aerodesign Micro Class - 2018 - Buzz Boxyear

The challenge for this year’s competition is to fit an aircraft in a box with its full payload: 2.75” outer diameter PVC pipes. The box is only 3.75” thick, meaning that there is very limited place to fit the aircraft inside the box.

As the manufacturing team lead, I streamlined the manufacturing process for the fragile wooden-structured wings and tested them in various loading conditions. The wings are also tested for belly landings as this aircraft did not have landing gear.

Earned:

1st Place Design Report

1st Place Overall

1st Place Payload Fraction

SAE Aerodesign 2017 - Buzz Kiteyear

Design: Rogallo Wing

The airplane needed to fit into a tube, be assembled, and then fly. The score was based on the exterior dimensions of the storage tube (smaller is better) and the empty weight of the aircraft (lighter is better).

As part of the manufacturing team, I designed and enhanced the way custom-designed locking joints are designed and manufactured using FDM 3D printers. I used Stratasys 3D printing software to custom design the internal structure of each layer to minimize the weight while meeting the loading requirements. These printed joints gave the team an immense edge, making us impossible to beat after 2nd round.

The design was awarded 1st place among 75 international teams.

AIAA Design Build Fly 2016 - Buzzedryoshka

The challenge is to design an aircraft that can carry a Gatorade bottle for 5 minutes and another aircraft that can carry the aircraft that carried the Gatorade bottle. The penalty function involved number of parts the small aircraft were broken into. Therefore, the small aircraft wasn’t disassembled. Instead, bigger airplane was designed to be an “Iron Man Suit” around the smaller airplane.

Awards:

2nd Place Report

2nd Place Overall